Special Article: Yeast-Based Products – Characterization and Productive Results for Beef Cattle

Per Ricardo Pereira Manzano* energetic Vanessa Olszewski**

The species yeasts Saccharomyces cerevisiae They are unicellular organisms important for the production of food, beverages, fuels and in the pharmaceutical industry.

In recent decades, studies have demonstrated the viability of different yeast-based products for the food and animal health industry with positive impacts on the animal protein production chain, replacing growth-promoting antibiotics and reducing the effects of mycotoxins on health, productivity and quality of foods of animal origin.

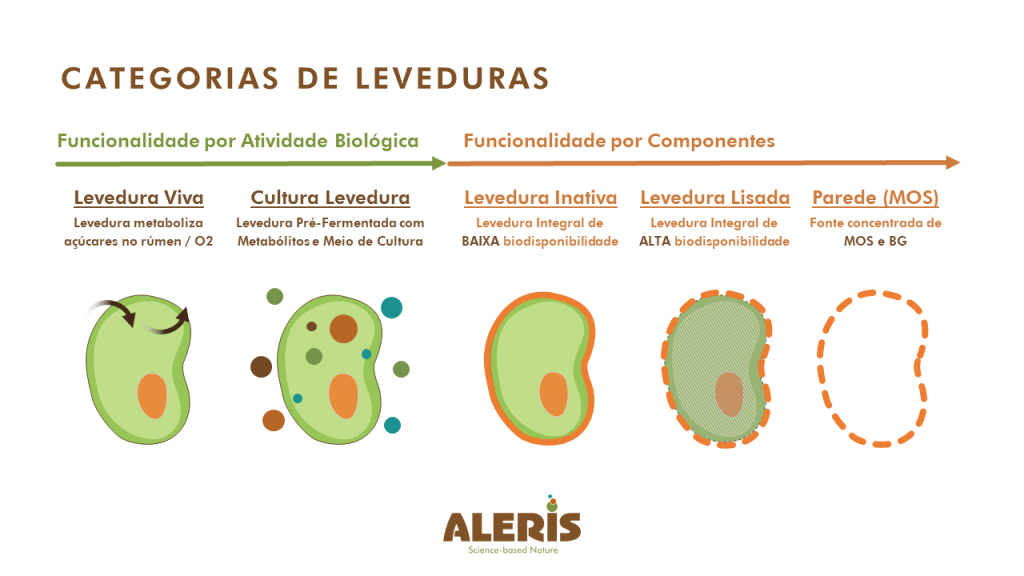

The main yeast-based products available for the animal feed market can be subdivided/classified into two groups, according to their functionality by biological activity or components (Figure 01).

Live – or active – yeast These are products with microorganisms that undergo a freeze-drying process, temporarily interrupting their activity to be packaged and made available to the market for inclusion in the feed and supplements provided to animals.

According to AAFCO (2013), a commercial product to be classified as active yeast in the North American market must have a count of 1.0 x 1010 cfu/g of commercial product.

Once ingested, these reach the rumen where they participate directly and actively in ruminal metabolism, removing free oxygen (O²) and positively influencing the bacteria that live in this system, especially those that digest fiber and consume lactic acid. In this way, the indirect action of controlling lactic acid in the rumen environment results in greater digestibility of the fibrous fraction of the diet and pH control, positively reflecting on food and energy consumption, improving productive efficiency and animal protein production.

However, products based on active yeast, as they are made up of live cells, impose some limitations on the production and conservation processes in feed, due to the loss of viability/activity of yeast cells over time. Also, the use of heat for pelletization or extrusion intensely reduces the viability of these microorganisms, unless they are protected. Other environmental factors such as temperature, sunlight, humidity and salinity contribute to reducing the viability of yeast cells during storage and the consequent supply of the effective quantity to the animals.

The second product in the group classified by biological activity is Yeast Culture, which is characterized as a product that contains a high concentration of metabolites previously obtained during a controlled fermentation process.

When we use Yeast Culture in cattle feed, we are providing these metabolites, which we call “growth factors”, with the aim of stimulating the growth of species present in the autochthonous (native) microbiota of the rumen, mainly fibrolytic bacteria (degrading fiber) and consumers of lactic acid – such as Megasphaera elsdenii.

The diversity of chemical classes included within the growth factors present in the culture medium, such as amino acids, organic acids, vitamins, among others, are obtained in a standardized fermentation process prior to supplying the animals, thus not depending on the viability of the cells. alive from Saccharomyces cerevisiae to act in the rumen. For this reason, the product is safer in ensuring that beneficial effects on indigenous target populations in the rumen environment are obtained. Another advantage is that environmental and feed production factors do not alter their composition and ability to promote the desired effect.

A Inactive yeast It is an important source of protein, with a limited supply of growth factors for the ruminal or intestinal microbiota, since these are contained in the cytoplasm surrounded by the cell wall.

To increase the functionality of its components, the application of a cell wall lysis process by hydrolysis or autolysis, causes greater exposure of its rich cytoplasmic content, in addition to increasing the availability of glucomannans present in the yeast cell wall. Thus, the Lysed Yeasts have the advantage of fractionating the cell wall, providing an important action on the immune system, protecting the intestinal epithelium against some pathogens, in addition to stimulating the growth of beneficial microbiota in the digestive system of animals, by exposing the metabolites present in the cytoplasm of the cell wall. Saccharomyces cerevisiae.

However, when compared to Yeast Culture, the amount of metabolites made available by the cell wall disruption process is smaller, significantly reducing the extent of its effect on the ruminal environment.

The product that has the greatest functionality classified by components is the purified cell wall, more commonly referred to as MOS. This wall is rich in mannanoligosaccharides and beta-glucans, with important and well-directed actions on the local and systemic immune system of animals, in addition to reducing the effects of pathogens and toxins on the integrity of the intestinal epithelium.

Also noteworthy is the ability of cell wall components to adsorb mycotoxins present in food, preserving animal health and the quality of products of animal origin such as meat, milk and eggs.

The most used products in cattle feeding are active yeasts and in recent decades, products based on yeast cultures have been gaining ground in this market. An experiment was recently conducted by Oliveira et al. (2021) evaluating the use of Yeast Culture and Autolyzed Yeast in feeding beef cattle with an initial weight of 370 kg, finished in confinement for 133 days.

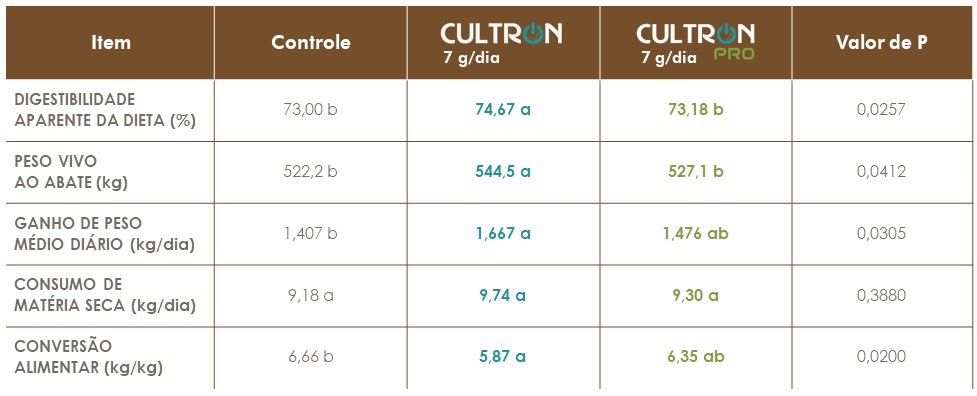

The use of Yeast Culture (Cultron) in the feeding of confined cattle demonstrated increased weight gain, greater apparent dietary digestibility (DAP) and better feed conversion (Table 01.)

The results presented by the use of Autolyzed Yeast proved to be intermediate between the results of the control treatment and the treatment with Yeast Culture.

Table 01. Diet apparent digestibility (DAP), live slaughter weight, average daily weight gain, dry matter intake and feed conversion of steers finished in confinement with two yeast-based products in the diet.

This same group of researchers carried out a second study – not yet published – with beef cattle of the same initial weight confined for 63 days.

Four treatments were evaluated in a 2 x 2 factorial scheme. One of the factors was Yeast Culture and the other factor, a commercial product formulated with fibrolytic enzymes. Again, the use of Yeast Culture showed an increase in the daily weight gain (1.644 kg) of the animals (P < 0.05) in relation to the control treatment (1.368 kg).

The daily weight gains provided by the exclusive use of enzymes (1.584 kg) or the combination of enzymes with Yeast Culture (1.581 kg) were not statistically different (P > 0.05) in relation to the exclusive use of Yeast Culture , but higher (p < 0.05) than the performance of animals in the control treatment.

In this second trial, it can be confirmed that the use of Yeast Culture also improved (P < 0.05) feed conversion in relation to the control, without depressing dry matter consumption.

In most national and North American feedlots, ionophore antibiotics are used as growth promoters, which provide improvements in feed conversion, at the cost of reducing dry matter consumption. The drop in dry matter consumption, especially at the end of the confinement period, is worrying, due to the animals' greater energy demand in this final phase of carcass finishing.

Often, weight gain in this final stretch becomes uneconomical for the feeder. Thus, Wagner et al. (2016) carried out a statistical meta-analysis to study the effect of including several Yeast Culture-based products in several experiments with confined beef cattle receiving diets with and without ionophores.

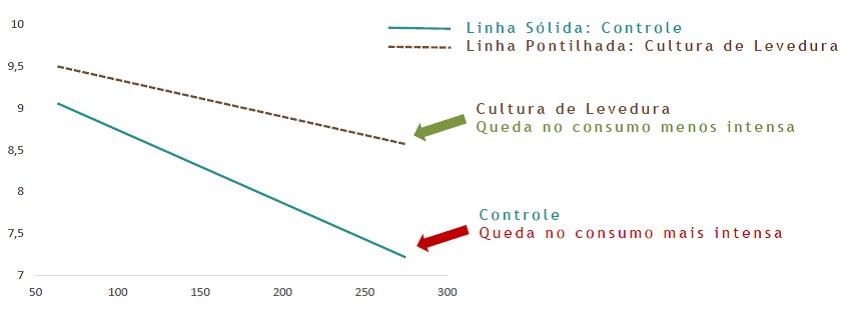

These authors observed that the use of Yeast Culture improved feed conversion (p < 0.01) in the finishing period and detected a less pronounced drop in the consumption curve of confined animals at the end of the confinement period (Figure 02) when Yeast Culture was provided.

The lower intensity of the drop in dry matter consumption without compromising the animals' feed efficiency is desirable, as it reduces the risk of financial loss in the last weeks of animal fattening, a common phenomenon in most input and cattle price scenarios fat in Brazil.

In conclusion, yeast-based products have long been used in animal nutrition. However, new technologies and analyzes have allowed an evolution in these products with much more targeted uses for specific purposes. The use of yeast culture in ruminant feeding has proven to be an excellent meat production tool with increased feed efficiency, improving economic performance in intensive beef cattle production systems. Furthermore, the possibility of replacing antibiotics with natural yeast-based products makes it possible to produce meat that is safe for human consumption, also contributing to the sustainability and balance of the environment.

Author